Ndedzipi mhando dzemajekiseni ekuumba zvinhu?

Jekiseni molding inzira yekugadzira inosanganisira kubaya zvinhu zvakanyungudutswa mugomba rekuumba kuti ribudise chimiro chaunoda.Jekiseni molding inogona kushandiswa kugadzira zvigadzirwa zvakasiyana-siyana, senge mapurasitiki, zvikamu zvesimbi, zvishandiso zvekurapa, nezvimwe.Nekudaro, hazvisi zvese zviwanikwa zvakakodzerwa nekuumba jekiseni.Isu tichakurukura mhando dzemajekiseni ekuumba zvinhu uye zvimiro zvavo, zvakanakira, uye zvazvakaipira.

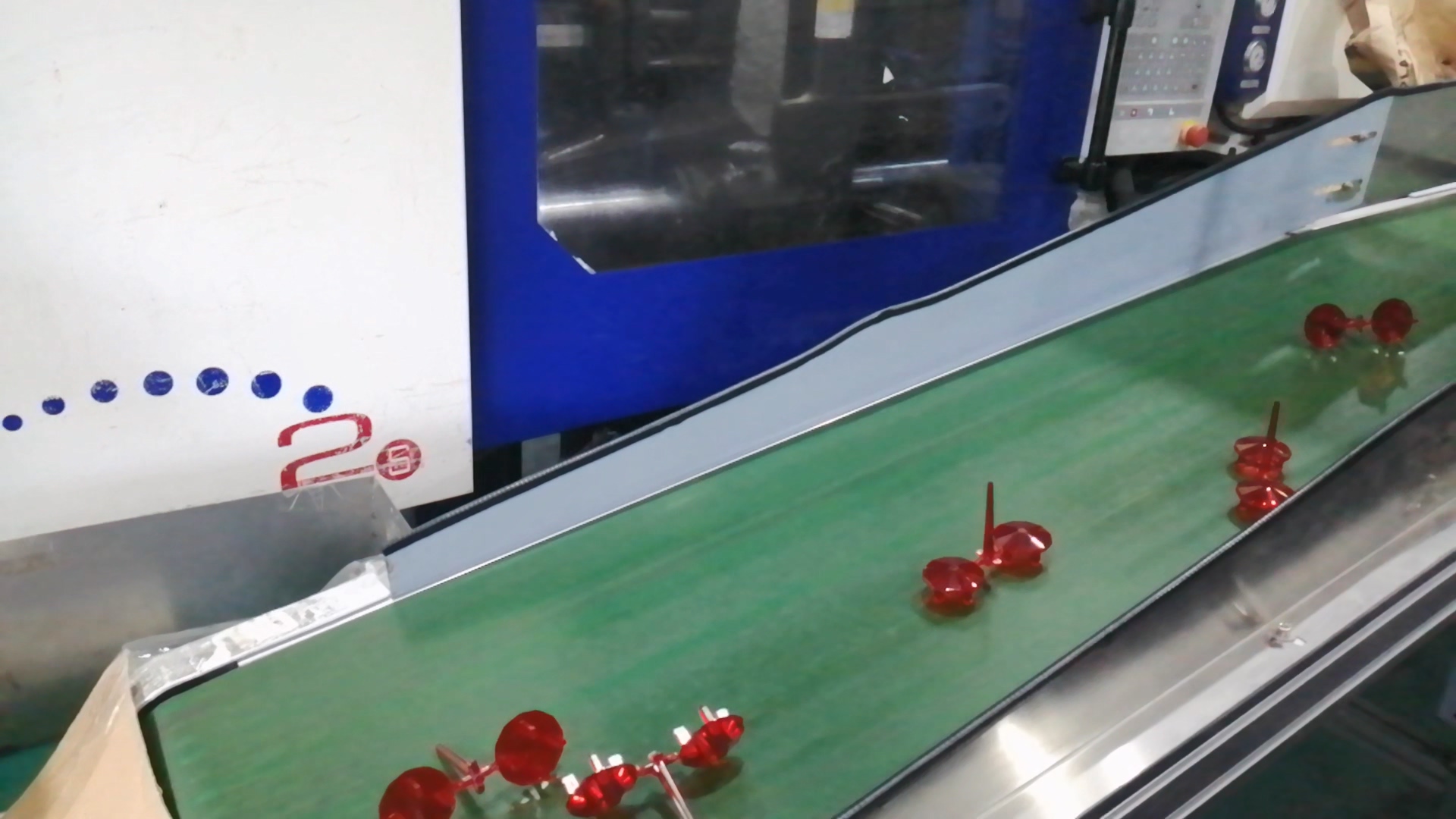

Mhando dzemajekiseni ekuumba zvinhu

Kune akawanda marudzi ezvishandiso zvekuumba jekiseni, asi zvinogona kuiswa muzvikamu zvina: thermoplastics, thermosets, elastomers, uye simbi.

Thermoplastics

Thermoplastics zvinhu zvinogona kudzokororwa kunyungudutswa nekusimbiswa nekudziya nekutonhodza.Ndiwo anonyanya kuzivikanwa mhando yejekiseni yekuumba zvinhu, inoverengera inosvika 80% yemusika.Thermoplastics ine yakakwirira kuchinjika, kusimba, uye kudzokorora.Mimwe mienzaniso ye thermoplastics ndeiyi:

- Polyethylene (PE): Chinhu chakaderera-chine chinopesana nemakemikari, hunyoro, uye kukanganisa.Inoshandiswa zvakanyanya kurongedza, midziyo, matoyi, uye pombi.

- Polypropylene (PP): Chinhu chine kuomarara kwakanyanya, simba, uye kupisa kuramba.Inoshandiswa kune zvikamu zvemotokari, zvishandiso zvekurapa, fenicha, uye midziyo.

- Polyvinyl chloride (PVC): Chinhu chine yakanaka kuvharisa magetsi, kunonoka kwemurazvo, uye mamiriro ekunze.Inoshandiswa kugadzira tambo dzemagetsi, mapaipi, mafittings, uye pasi.

- Polystyrene (PS): Chinhu chine kujeka kwakanaka, kuomarara, uye kugadzikana kwedimensional.Inoshandiswa kumakapu anoraswa, ndiro, kucheka, uye kurongedza.

- Acrylonitrile butadiene styrene (ABS): Chinhu chine simba rekuita zvakanaka, kuoma, uye kupera kwepamusoro.Inoshandiswa kugadzira dzimba, ngowani, matoyi, uye zviridzwa zvemimhanzi.

- Nylon: Chinhu chine yakanaka abrasion kuramba, kupfeka kuramba, uye michina zvinhu.Inoshandiswa kugadzira magiya, mabearings, bushings, uye fasteners.

Thermosets

Thermosets zvinhu zvinosangana nekemikari yekuita kana yapiswa uye inoumba chimiro chisingaperi chisingakwanise kudzoreredzwa kana kuumbwa patsva.Thermosets ane high thermal kugadzikana, makemikari kuramba, uye mechanical simba.Mimwe mienzaniso ye thermosets ndeiyi:

- Epoxy: Chinhu chine yakanakisa adhesion, magetsi insulation, uye ngura kuramba.Inoshandiswa kugadzira machira, adhesives, laminates, uye kompositi.

- Phenolic: Chinhu chine yakanyanya kupisa kupisa, kunonoka kwemurazvo, uye kuoma.Inoshandiswa kushandura magetsi, zvigadziko, mapulagi, uye zvibato.

- Polyester: Chinhu chine yakanaka kuchinjika, kusimba, uye mamiriro ekunze.Inoshandiswa kugadzira zvikepe, mitumbi yemotokari, matangi, uye pombi.

- Urea formaldehyde: Chinhu chine mutengo wakaderera, kuomarara kwakanyanya, uye yakanaka dimensional kugadzikana.Inoshandiswa kupfundo, mabhatani,

zvibato, uye fenicha.

Elastomers

Elastomers zvinhu zvinogona kutambanudzwa kana kumanikidzwa uye kudzokera kune chimiro chazvo chepakutanga kana simba rabviswa.Elastomers ane elasticity yakakwirira,

kusimba, uye kubatwa nekuvhunduka.Mimwe mienzaniso yeelastomers ndeiyi:

-Silicone: Chinhu chine yakanakisa kupisa kupisa, ozone kuramba, uye biocompatibility.Inoshandiswa kune zvisimbiso, gaskets, tubing, uye michina yekurapa.

- Rubha: Chinhu chine yakanaka abrasion kuramba, kuneta kuramba, uye vibration damping.Inoshandiswa kumatayi, mabhandi, hoses, uye grommets.

- Thermoplastic elastomers (TPEs): Chinhu chinosanganisa zvimiro zve thermoplastics uye elastomers.Inogona kugadzirwa senge thermoplastics, asi ine kuchinjika uye elasticity ye elastomers.Inoshandiswa kubata, mabumpers, mateti, uye zvisimbiso.

Metals

Metals zvinhu zvine high conductivity, density, and melting point.Anowanzo kubaiwa muforoma pachishandiswa nzira inokosha inonzi metal injection molding (MIM) .MIM inosanganisira kusanganisa simbi hupfu nemabinders kuita feedstock inogona kubaiwa mu mold.Chikamu chakaumbwa chinobva chapiswa kuti chibvise mabhainda uye kunyungudutswa kuita dense metal part.MIM inogona kugadzira maumbirwo akaomarara ane high precision,surface finish, and mechanical properties.Mimwe mienzaniso yesimbi inogona kushandiswa kuMIM ndeiyi:

-Simbi isina simbi: Chigadzirwa chine kukwirira kwekuora, kusimba, uye kuomarara.Inoshandiswa pakuvhiya zviridzwa, zvekuisa mazino, zvishongo, uye wachi.

- Titanium: Chinhu chine simba rakakura-ku-huremu reshiyo, bio-compatibility, uye kupisa kupisa.Inoshandiswa kune aerospace zvikamu, midziyo yemitambo, kudyara kwemazino, uye midziyo yekurapa.

-Simbi: Chinhu chine mutengo wakaderera, magineti zvivakwa, uye kupfeka kuramba.Inoshandiswa kune zvikamu zvemotokari, maturusi emagetsi, magiya, uye mabhengi.

Mhedziso

Jekiseni molding inzira inosiyana-siyana inogona kugadzira zvigadzirwa zvakasiyana-siyana uchishandisa mhando dzakasiyana dzezvinhu.Rudzi rumwe norumwe rwezvinhu zvine maitiro aro,

zvakanakira, uye zvisingabatsiri.Naizvozvo, zvakakosha kuti usarudze chinhu chakakodzera kune chaiyo application uye dhizaini zvinodiwa.Injection molding inogona zvakare kusanganiswa nemamwe maitiro, senge isa molding, overmolding, uye co-jekiseni, kugadzira akawanda-material. kana zvigadzirwa zvemavara akawanda.Injection molding inzira inokurumidza, inoshanda, uye inodhura yekugadzira zvigadzirwa zvemhando yepamusoro.

Chii chinonzi injection molding?

Jekiseni molding inzira yekugadzira iyo inogadzira zvikamu zvepurasitiki nekupinza zvinhu zvakanyungudutswa muforoma.Maitiro acho ane matanho mana makuru: clamping, jekiseni, kutonhora uye ejection.

Clamping: Iyo mold inoumbwa nehafu mbiri, inonzi mhango uye musimboti, iyo yakasungirirwa kune clamping unit.Iyo clamping unit inobata mold yakavharwa pasi pekumanikidzwa panguva yejekiseni nematanho ekutonhora.Simba rekusunga rinoenderana nehukuru uye chimiro chechikamu, pamwe chete nezvinhu zvakashandiswa.

Jekiseni: Zvinhu zvepurasitiki, kazhinji zviri muchimiro chepellets kana granules, zvinodyiswa mubhodhoro rinopisa, umo rinonyungudutswa uye rinosanganiswa ne screw inotenderera.Iyo screw inoshandawo seplunger, ichisaidzira purasitiki yakanyungudutswa muforoma kuburikidza nemuromo.Iyo jekiseni kumhanya, kudzvanywa uye tembiricha inodzorwa kuve nechokwadi chekuti zvinhu zvinozadza mold zvachose uye zvakaenzana.

Kutonhodza: Purasitiki yakanyungudutswa mukati me mold inotanga kutonhora nekusimba, ichitora chimiro chechikamu.Nguva yekutonhora inoenderana nehupamhi uye geometry yechikamu, pamwe chete nezvinhu zvemukati.Munguva iyi, mold inoramba yakavharwa uye pasi pekumanikidzwa kudzivirira shrinkage kana deformation.

Ejection: Mushure mokunge chikamu chacho chatonhora zvakakwana, mold inovhurwa uye chikamu chinobudiswa nemaitiro anonzi ejector system.Iyo ejector system inogona kuva mapini, mablades kana majeti emhepo anosundira chikamu kubva muforoma.Chikamu chinobva chabviswa pamushini uye chinoongororwa kwemhando.

Jekiseni molding inzira inosiyana-siyana uye inoshanda inogona kugadzira zvikamu zvakaoma uye zvemhando yepamusoro muhuwandu hukuru uye nemarara akaderera.Inoshandiswa zvakanyanya mumaindasitiri akasiyana, akadai semotokari, zvekurapa, zvinhu zvevatengi, zvemagetsi nezvimwe.

Chii chakakosha uye basa remajekiseni molds?

Jekiseni molding inzira inoshandiswa zvakanyanya yekugadzira iyo inogona kuburitsa zvikamu zvepurasitiki zvine maumbirwo akaomarara uye nehupamhi hwepamusoro.Jekiseni rekugadzira rinosanganisira kubaya purasitiki yakanyungudutswa mugomba, umo inotonhodza nekuoma muchimiro chaunoda.Iyo mold cavity inowanzo gadzirwa nesimbi kana ceramic, uye inogona kugadzirwa kuburitsa akawanda zvikamu kamwechete.

Kukosha uye basa rekuumba jekiseni rakakosha mumaindasitiri mazhinji, akadai semotokari, zvekurapa, aerospace, zvemagetsi zvevatengi, nezvimwe.Jekiseni molding inogona kupa akawanda mabhenefiti, akadai se:

-Kubudirira kwekugadzirwa kwepamusoro: jekiseni molding inogona kuburitsa huwandu hukuru hwezvikamu munguva pfupi, ine marara mashoma uye zvimedu.Majekiseni ekuumba michina anogona kushanda nguva dzose, uye anogona otomatiki kudzikisa mutengo wevashandi uye kukanganisa kwevanhu.

- Hunhu hwepamusoro uye kuenderana: jekiseni kuumba inogona kuburitsa zvikamu zvine yakakwira dimensional kurongeka uye kupera kwepamusoro, pamwe chete nemaitiro akafanana uye kuita.Jekiseni molding inogona zvakare kuderedza kuremara uye mutsauko muchigadzirwa chekupedzisira, nekudzora tembiricha, kudzvanywa, uye kumhanya kwekuita jekiseni.

- Dhizaini inochinjika: jekiseni kuumba inogona kuburitsa zvikamu zvine yakaoma geometries, yakaoma kunzwisisa, uye akawanda mavara kana zvinhu.Jekiseni molding inogonawo kugadzirisa shanduko mukugadzira kana kutsanangurwa kwezvikamu, nekugadzirisa mhango ye mold kana kushandisa akasiyana epurasitiki zvinhu.

- Mutengo-kushanda: jekiseni kuumba kunogona kuderedza mutengo wese wekugadzira, nekudzikisa kushandiswa kwezvinhu, kuderedza kuungana uye kupedza mashandiro, uye kuwedzera kusimba uye hupenyu hwezvikamu.

Jekiseni molding imhando dzakasiyana-siyana uye yakavimbika yekugadzira iyo inogona kusangana nezvinodiwa zveakasiyana maindasitiri uye maapplication.Nekudaro, kuumba jekiseni zvakare kune zvimwe zvinonetsa uye zvinogumira, senge:

-Kudyara kwekutanga kwekutanga: jekiseni kuumbwa kunoda mutengo wepamusoro wekugadzira nekugadzira mold cavity, pamwe nekutenga nekuchengetedza jekiseni rekuumba muchina.Iyo mold cavity inowanzogadzirirwa chikamu chimwe nechimwe, uye inogona kudhura uye inopedza nguva kugadzira.

-Kusarudzwa kwezvinhu zvakaganhurirwa: Jekiseni kuumba inogona chete kushandisa thermoplastic zvinhu zvinogona kunyunguduka uye kuyerera pasi pekupisa kwakanyanya uye kumanikidzwa.Zvimwe zvinhu zve thermoset kana zvinhu zvinoumbwa zvinogona kunge zvisina kukodzera kuumbwa jekiseni, kana zvingangoda zvekuwedzera kana marapirwo kuti vavandudze kuumbwa kwavo.

-Kukanganisa kwezvakatipoteredza: Jekiseni kuumba kunogona kuburitsa kupisa kwakawanda kwemarara uye kubuda panguva yekunyunguduka uye kutonhora kwepurasitiki zvinhu.Jekiseni molding inogona zvakare kuburitsa tsvina yepurasitiki kubva kune yakawandisa zvinhu zvinobuda kunze kwegomba remuvhu kana kuumba kumucheto kwechikamu.Zvinhu zvinoraswa izvi zvinoda kudzokororwa kana kuraswa zvakanaka, kuti zvideredze kukanganisa kwazvinoita.

Jekiseni molding inzira yakaoma uye ine simba inoda kunyatsoronga, dhizaini, uye optimization.Majekiseni ekuumba mainjiniya anofanirwa kufunga zvinhu zvakawanda, senge:

-Kusarudzwa kwezvinhu: Kusarudzwa kwezvinhu zvepurasitiki kunokanganisa zvivakwa, kuita, kutaridzika, uye mutengo wechikamu chekupedzisira.Zvinhu zvepurasitiki zvinofanirwa kuenderana nezvinodiwa zvechikamu chebasa, nharaunda, aesthetics, uye kusimba.Iyo yepurasitiki zvinhu zvinofanirwawo kuve nekuyerera kwakanaka, kugadzikana, shrinkage, uye kuenderana negomba rekuumbwa.

- Mold dhizaini: Dhizaini ye mold cavity inotaridza chimiro, saizi, mhando, uye kuoma kwechikamu chekupedzisira.Iyo mold cavity inofanirwa kunge iine mhepo yakakwana, kutonhora, ejecting, uye clamping masisitimu, kuve nechokwadi chekuita jekiseni rakatsetseka uye rinoshanda.Iyo mold mhango inofanirwawo kunge iine yakakodzera dhizaini angles, kukora kwemadziro, kushivirira, uye pamusoro pekupedzisira, kudzivirira kuremara uye deformation muchikamu chekupedzisira.

-Maitiro maparamita: Iwo marongero eiyo jekiseni maitiro anokanganisa mafambiro ekuyerera, kutonhora mwero, kudzvanywa kugovera, uye crystallization yezvinhu zvepurasitiki.Iyo maitiro maparamendi anofanirwa kugadziridzwa kuti akwidzise kuzadza, kurongedza, kubata, kutonhora, uye ejecting matanho ekuita jekiseni.Iyo maitiro paramita anofanirwawo kutariswa uye kudzorwa kuchengetedza kuenderana uye kunaka mune yekupedzisira chigadzirwa.

Jekiseni molding isimba uye rakakurumbira kugadzira maitiro anogona kugadzira emhando yepamusoro zvikamu zvepurasitiki zvine maumbirwo akasiyana uye mabasa.Jekiseni molding inoita basa rakakosha mumaindasitiri mazhinji anovimba nezvigadzirwa zvepurasitiki kuita kwavo uye pundutso.Jekiseni molding zvakare inonetsa uye inoshanduka nzira inoda kugara ichivandudza uye kuvandudzwa kuti isangane nekushanduka kwezvinodiwa uye zvinotarisirwa nevatengi.