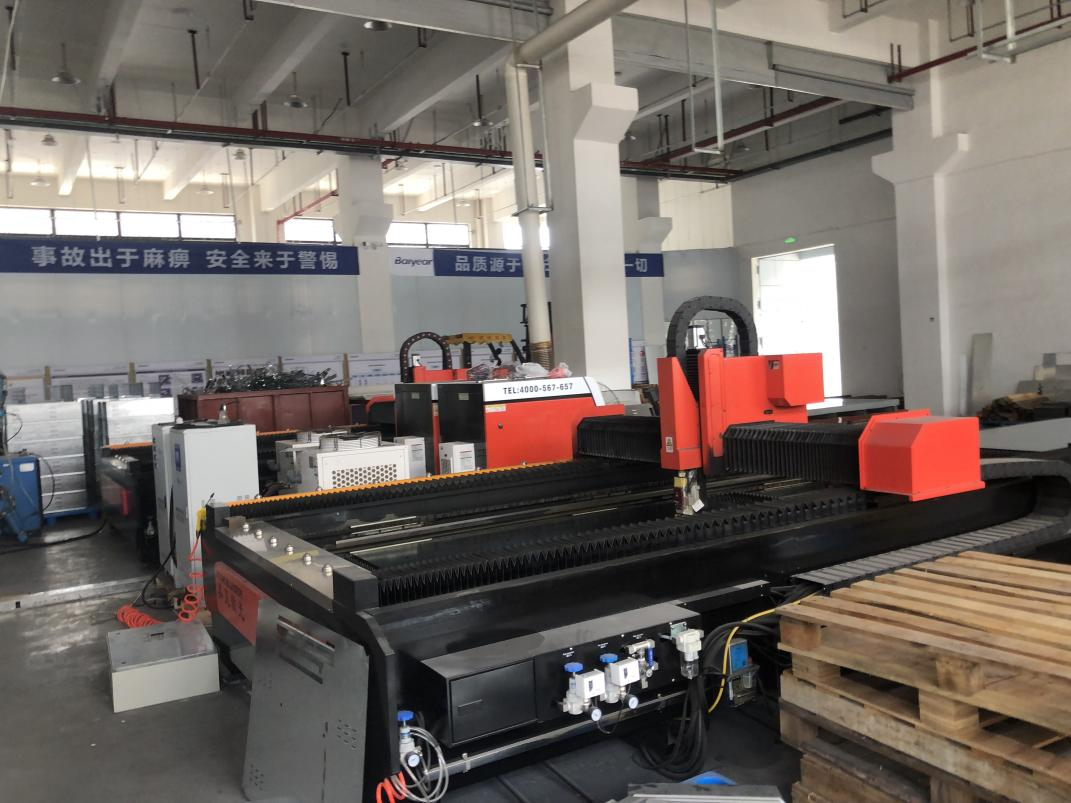

NaAndy anobva kuBaiyear fekitori

Yakadzorerwa November 1, 2022

Sheet metal haisati yave netsanangudzo yakakwana.Zvinoenderana netsanangudzo iri mujenari renyanzvi dzekune dzimwe nyika, inogona kutsanangurwa se: Sheet simbi inzira inotonhora yekushanda yemarata esimbi matete (kazhinji ari pasi pe6mm), kusanganisira kugera, kubaya / kucheka / kusanganisa, kupeta, welding, riveting, splicing. , kuumba (zvakadai semuviri wemotokari), nezvimwewo. Chinhu chayo chinoshamisa ndechokuti ukuru hwechikamu chimwe chete.

Sheet simbi yekucheka inzira yakakosha yekugadzira mapepa esimbi zvigadzirwa.Inosanganisira kucheka kwechinyakare, kuvharika, kupeta kuumba uye dzimwe nzira uye magadzirirwo paramita, pamwe neakasiyana siyana anotonhora ekutsika zvimiro uye maitiro paramita, akasiyana siyana ekushandisa misimboti uye nzira dzekushandisa, pamwe nehunyanzvi hwekutsikisa tekinoroji uye tekinoroji nyowani.

Kune chero pepa resimbi chikamu, ine imwe nzira yekugadzirisa, iyo inonzi inonzi teknolojia.Nekusiyana kwechimiro chezvikamu zvesimbi, iyo tekinoroji maitiro anogona kunge akasiyana, asi iyo yakazara haipfuure zvinotevera pfungwa.

1. Dhizaina uye dhirowa chikamu chekudhirowa kweshizha rayo simbi zvikamu, inozivikanwawo semaonero matatu.Basa rayo ndere kuratidza chimiro chepepa rayo simbi zvikamu nenzira yekudhirowa.

2. Dhirowa dhayagiramu isina kuvhurwa.Ndiko kuti, vhura chikamu chine chimiro chakaoma kuita chikamu chakati sandara.

3. Kusavhara.Kune nzira dzakawanda dzekuvhara, kunyanya nenzira dzinotevera:

a.Kucheka muchina wekucheka.Iko kushandisa muchina wekuveura kucheka chimiro, kureba uye upamhi hwedhirowa yakawedzerwa.Kana paine punching uye kucheka kwekona, saka shandura muchina wekubaya kuti ubatanidze iyo kufa punching uye kucheka kwekona kuita.

b.Punch blanking.Iko kushandisa chibhakera kurovera iyo furati chikamu chimiro mushure mekunge zvikamu zvazarurwa pandiro mune imwe kana kupfuura nhanho.Iyo ine mabhenefiti emaawa mapfupi-awa, kushanda kwakanyanya, uye inogona kuderedza mari yekugadzira.

c.NC CNC isina chinhu.Kana NC ichivhara, danho rekutanga nderekunyora iyo CNC machining chirongwa.Iko kushandisa software yekugadzira dhiyagiramu yakadhirowewa yekuwedzera kuita chirongwa chinogona kuzivikanwa neNC CNC muchina wemuchina.Rega itevere zvirongwa izvi nhanho nhanho pane iron plate Pa, baya kunze chimiro chezvikamu zvayo zvakafuratira.

d.Laser kucheka.Iyo inoshandisa iyo laser yekucheka nzira yekucheka chimiro chechimiro chezvikamu zvayo zvakafuratira pandiro yesimbi.

4. Flanging uye kubaya.Flanging inodaidzwa zvakare kunzi kuchera gomba, ndiko kudhirowa gomba rakakura zvishoma pane diki diki, uye wobva wabaya buri.Izvi zvinogona kuwedzera simba rayo uye kudzivirira kutsvedza.Inowanzo shandiswa kugadzira sheet simbi ine yakatetepa ndiro ukobvu.Kana iyo hobvu yeplate yakakura, senge kukora kweplate pamusoro pe 2.0, 2.5, nezvimwewo, tinogona kubaya zvakananga pasina kubhururuka.

5. Punch processing.Kazhinji, kurovera nekucheka pakona, kubaya blanking, kubaya convex hull, kubaya uye kubvarura, kubaya uye dzimwe nzira dzekugadzirisa dzinoshandiswa kuzadzisa chinangwa chekugadzirisa.Kugadziriswa kunoda molds dzinoenderana kuti upedze kushanda.Kune maconvex hull molds ekubaya maconvex hulls, uye kubvarura kugadzira mold yekubaya nekutsemura.

6. Pressure riveting.Nezve fekitori yedu, kumanikidza riveting studs, kumanikidza riveting nzungu, pressure riveting screws, nezvimwe zvinowanzoshandiswa.Riveted to sheet metal parts.

7. Kupeta.Kupeta kupeta 2D flat parts kuita 3D parts.Kugadziriswa kwayo kunoda muchina wekupeta uye inopetwa inofa kuti ipedze kuvhiya.Iyo ine zvakare imwe yekukotama kutevedzana.Peta rekutanga risingapindire rinoburitsa peta rekupedzisira rinokanganisa.

8. Welding.Welding ndeye kubatanidza zvikamu zvakawanda pamwechete kuti zvizadzise chinangwa chekugadzirisa kana kuti weld seam yepadivi yechikamu chimwe chete kuwedzera simba rayo.Nzira dzekugadzirisa dzinowanzobatanidza zvinotevera: CO2 gasi shielded welding, argon arc welding, Spot welding, robot welding, nezvimwewo.Kazhinji kutaura, CO2 gasi shielded welding inoshandiswa simbi plate welding;argon arc welding inoshandiswa kune aluminium plate welding;robhoti welding inonyanya kushandiswa muzvinhu Inoshandiswa kana zvikamu zvakakura uye welding seam yakareba.Zvakadai semakabati welding, robhoti welding inogona kushandiswa, iyo inogona kuchengetedza akawanda mabasa uye kuvandudza kushanda zvakanaka uye welding mhando.

9. Kurapa kwepamusoro.Kurapa kwepamusoro kunowanzo sanganisira phosphating firimu, electroplating multicolored zinc, chromate, pendi yekubikira, oxidation, nezvimwe. Phosphating firimu rinowanzo shandiswa kutonhora-akakungurutswa masheets uye electrolytic sheet, uye basa rayo rinonyanya kupfekedza pamusoro pechinhu.Firimu inodzivirira inoshandiswa kudzivirira oxidation;chechipiri ndechekusimudzira kunamatira kwepende yayo yekubheka.Electroplating colorful zinc inowanzoshandiswa kurapa pamusoro pemahwendefa anotonhora-akakungurutswa;chromate uye oxidation inowanzoshandiswa pakurapa kwepamusoro kwearuminiyamu mahwendefa uye aluminium profiles;yaro chaiyo Kusarudzwa kwekugadzirisa nzira inogadziriswa maererano nezvinodiwa nemutengi.

10. Gungano.Iyo inonzi musangano ndeyekuunganidza zvikamu zvakawanda kana zvikamu pamwe chete neimwe nzira kuti zvive chinhu chakakwana.Chimwe chezvinhu zvekuteerera ndechekudzivirirwa kwezvinhu, kwete kukwenya uye mapundu.Gungano ndiro danho rekupedzisira pakupedzwa kwechinhu.Kana zvinhu zvisingakwanisi kushandiswa nekuda kwekukwenya uye kuputika, zvinoda kugadziriswa uye kugadziriswa, izvo zvinoparadza nguva yakawanda yekugadzirisa uye kuwedzera Mutengo wechinhu chacho.Nokudaro, kunyanya kukoshesa kunofanira kubhadharwa kune kuchengetedzwa kwechinhu chacho.

Nguva yekutumira: Nov-29-2022